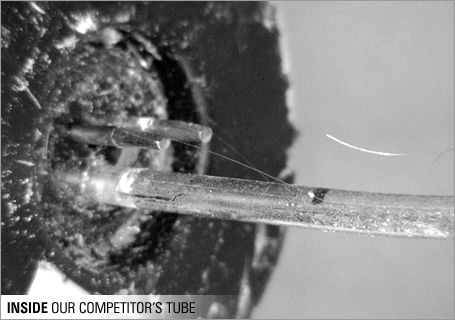

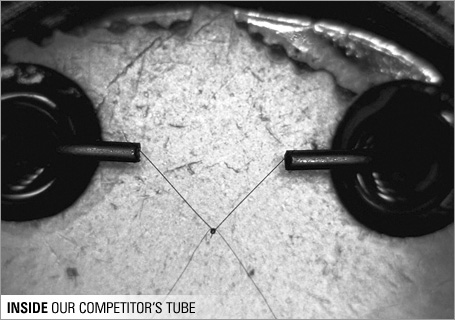

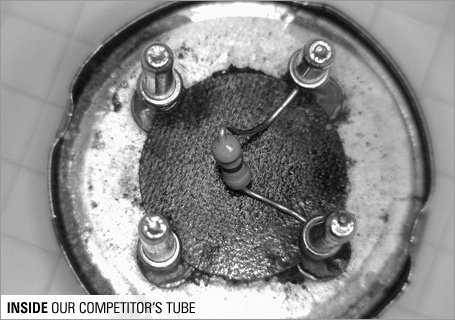

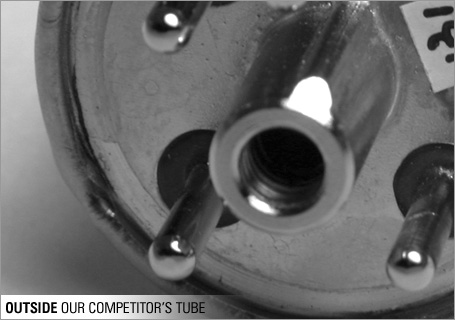

All vacuum gauge tubes are not created equal. We know. We looked inside.

Because Hastings employs proprietary fixturing technology that eliminates physical handling of components, the inside structure of our vacuum tubes is unsurpassed.

Using a clean flame and resistance welding, we create a precision junction between thermocouple wires. We attach the thermocouples to electrical vacuum feed through pins using very sophisticated precision weld technology. Every installed thermocouple is resistance tested to precise specifications.

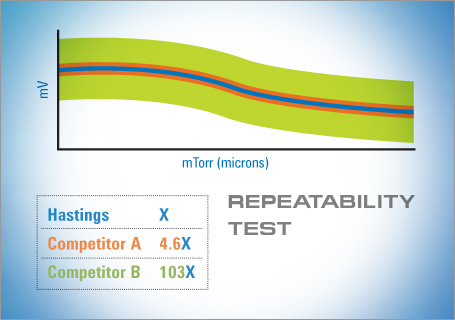

Play our slideshow (to the right) or download our brochure for the full story.